|

Nanotube

Technology

Properties

of FIBRIL Nanotubes Properties

of FIBRIL Nanotubes

Commercially

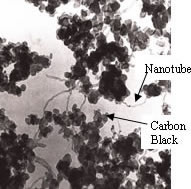

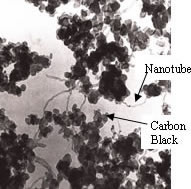

manufactured FIBRIL nanotubes are produced from high purity, low molecular

weight hydrocarbons in a proprietary, continuous, gas phase, catalyzed

reaction. They are parallel, multi-walled carbon nanotubes. The outside

diameter of the tube is approximately 10 nanometers and the length is

over 10 microns. As produced, FIBRIL nanotubes are intertwined together

in agglomerates. However, Hyperion has developed proprietary techniques

to disperse nanotubes.

Advantages

of FIBRIL Nanotubes as a Conductive Additive Advantages

of FIBRIL Nanotubes as a Conductive Additive

The

unique morphology of FIBRIL nanotubes allows them to be used commercially

to make high performance conductive plastics. Nanotubes have a very

high aspect ratio (length divided by diameter) of 1000. This means that

a very low loading is needed to form a percolating (conductive) mixture

with a polymer compared to additives with lower aspect ratios.

The

advantages of a low loading of a very small conductive additive will

be discussed in the applications sections.

Related

Article

Designing

for ESD Protection Using FIBRIL Nanotubes (95KB PDF)

|

Properties

of FIBRIL Nanotubes

Properties

of FIBRIL Nanotubes Advantages

of FIBRIL Nanotubes as a Conductive Additive

Advantages

of FIBRIL Nanotubes as a Conductive Additive